.

Our local model railroad club is a round robin type of club so every Tuesday we go to another member's home to run trains, watch videos or work on their layout. I signed up for the Tuesday after Memorial Day 2009 and bought more materials than I needed but wanted to be ready. I got a good turnout but we did not quite get everything accomplished I had desired. It always seems to go a little slower and when you have a bunch of guys all trying to do something it is almost as difficult as herding cats. As luck would have it the following Tuesday was dark as no member had asked to have it so I grabbed it and had the crew back over the next week. We still did not get everything done but the foundation of the walls was in place.

.

We did things a bit different from the first wall seen in the earlier blog post. This time we were supporting the wall on top of the "L-girder" benchwork. Also I wanted the garage door to still operate so the wall had to stop short of the ceiling. There were some questions about structural stability, but that was solved using some curves in the wall as well as putting a top plate along the entire wall. The sections that could had the top plate secured to the ceiling. Those that had to clear the garage door had the top plate on the top of the wall. Again, just like a big "I" beam.

.

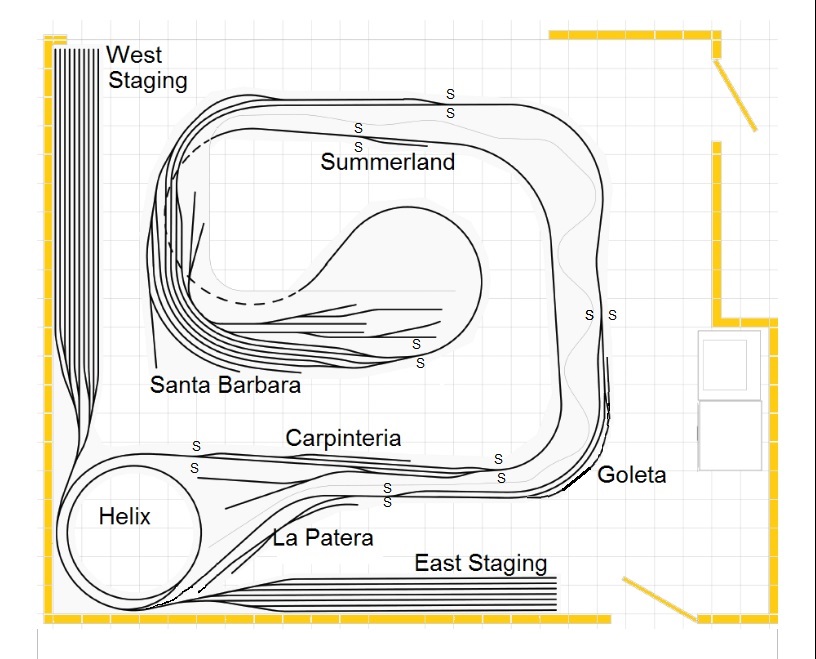

We did put up several 2x4 supports floor to ceiling. The 2x4 is screwwed to a block of wood that is secured to the floor using adhesive (liquid nails) and a masonry nail driven with a powder charge. One of these was later removed as it was not connected and the wall was structurally sound without it. In addition, I had 4 steel "C" supports fabricated to support the wall over some of the Santa Barbara area - where the Depot will go.

To form the curvature we took 1x4's or 1x6's and cut the curve into that and used it to make a sandwich with the 1/8" wall in between. In fact we cut four of the "sandwich" boards all at once so that we had a bottom and a top as well as two stiffeners for the two intermediate levels of track. One half of the bottom sandwich was secured to the "L-girder" benchwork and the same was done for the top which was secured to a plate on the ceiling. The wall was then curved into place and the second half of the "sandwich" was added. As the walls progressed around the layout, a lap of 6"-8" was made from one piece of 1/8" ply to the next. Once all the wall was in place under the garage door, another plate was added on top of the sandwich to tie it all together.

We only got two or three sections up during the club work sessions. Afterward I got my wife to help with cutting the walls and screwing on the 1x2's at the lap joints. When it was all up, I used dry wall joint compound to feather the lap joints. After it was smoothed - several applications of dry wall joint compound - I primed and painted them July 3 and we are now good to go.